RV Dump Valve Lubrication | RV Mods

This mod does not compare in complexity to some of the other mods we have done, but it ranks right up there with the other big ones in the “performance and functionality” category for our motorhome. It also tops the list in the “a good night’s sleep” category. It is a five minute mod that has earned its place on the all-star team.

Sticky dump valves. How do you fix them?

We have always had the problem, in one form or another, on our various motorhomes, and I’ve never really been able to figure out how to crack the code on being able to lubricate the blades and blade housings. And, I’ve always worried that someday we would be faced with some sort of disaster at the dump station; either not being able to get the valve open, or have it stick part way, or not be able to get it closed fully. The internet is full of stories regarding these problems, and there are quite a few ideas on how to get those things lubricated, but none of them have really worked for us.

So, I did some testing. We have a third gate valve at the dump connection, acting as a catch valve in case of a leaky black or grey valve, and I remove it at the end of the season. While it was in the basement over one winter, I tested out the “drill a hole in the casing, spray in some lubricant, and then put a screw in the hole” trick…

Here is the third dump valve I experimented with; you can see the small screw I inserted to close the hole I drilled in the end of the valve housing:

It became clear that this trick would only work on the valves with a direct pull handle – this will not work on a cable operated valve, as you can’t get to the valve housing on those cable designs. But, spraying in some lube inside the valve housing, and then sealing it up with a screw, did provide a good measure of valve lubrication. For a dump valve with a direct pull handle, this turned out to be a pretty good idea. If you have a direct pull dump valve and have not seen this trick, have a look here:

Drill a Hole in the Valve Housing Trick - Direct Pull handle only

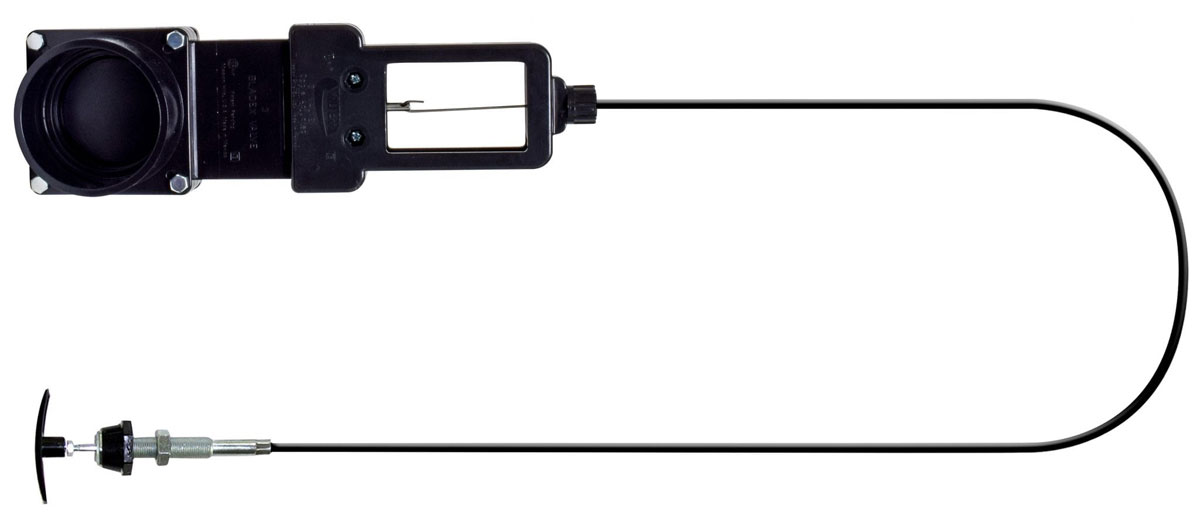

But, again, this will not work on the cable actuated dump valves we have on our View / Navion, as the valve housing is surrounded by a bolt-on tower that supports the cable pull actuator, and it is too impractical to take this assembly apart every time you want to lubricate the valve. This photo shows what a cable actuated valve looks like - note the bolt-on tower that the direct pull dump valve above does not have:

While doing my experiment on that direct pull dump valve I use as a safety valve, I concluded that the absolute best way to get lubricant onto the blade valve and its blade sheath was to simply spray it on directly. If you sprayed lubricant on the valve with the blade valve fully closed, the lubricant would run down and smear the blade sheath, and when you opened the valve the lubricant would run into the valve sheath and disperse in its track. When you closed the blade valve the lubricant would be pushed along the sheath track and up to the top of the blade valve. With the blade valve fully open, the lubricant would penetrate into the sheath track, and wait to lubricate the valve as it closed. (With the “YouTube drill a hole in the valve housing trick” you lubricate the bottom of the blade valve, but not the sheath and its rubber seals.)

Now, as you know, no RV or dump valve manufacturer gives you the capability to spray on some lubricant directly to your dump valves! Wouldn’t that be the easiest thing to do? But, maybe too easy … I guess they would not sell as many dump valves if there was a way for us to actually maintain them and make them last for years and years.

Spray some lubricant on directly … why not? When trying to figure out how to do this, I reminded myself that there are lots of fluid vessels and containers that have some sort of access port to allow for inspection or maintenance. So, why not a piece of RV plumbing? Why can’t you create an access port to give you the capability to maintain an RV dump valve?

Here is what I came up with – a very small hole directly opposite a dump valve that would allow you to get a lubricant spray straw up close to the valve. I used a 9 / 64th drill bit to create a small hole, and then with a 10” lubricant spray straw I was able to get some silicone spray directly onto the blade valve and its rubber seal sheath. To cover up the hole to protect against leakage, for the very remote times when there actually is fluid in the pipe, I simply used a piece of vinyl / PVC electrical tape to do the job. Worried about leakage? Well, we’ve got a 3 inch hole at the end of the sewer pipe that we put a cap on, that most of the time holds, so, to be honest, I’m not particularly worried about a 9 / 64th inch hole covered up with some very sticky tape.

Here is the section of plumbing that is directly opposite my black tank dump valve:

This is the 9 / 64th inch hole I drilled in the ABS pipe, and the next photo shows you the clearance for the 10” spray stray I used. If you push the straw in about seven inches, you will hit the face of the dump valve blade, square on:

When all done, I covered up the hole with some electrical tape.

The lubricant I used was this silicon lube, safe for plastic and rubber:

The only thing I had to buy for this mod was the 10” spray straw, but if you don’t want to find one of those, I don’t see why the standard spray straw that comes with your spray lubricant would not work pretty well either. (I’m guessing that having a longer straw allows you to get up close to the rubber sheath seals for better coverage, but since I couldn’t see what was going on in there – it really is just a guess.)

Aside from lubricating the pull handle shaft at the wet bay, and the valve pull shaft on the tower that guides the pull cable up at the valve housing, all I did was spray some silicon lube on the closed blade valve, opened the valve and sprayed again, and then worked the valve back and forth to ensure the silicone found its way into the rubber blade seals.

I repeated this whole process for the grey dump valve as well.

The before and after results were quite remarkable – the light force required and the smoothness on the pull cable was as if the RV had just come out of the factory.

Working better than I had hoped for - lubricating the dump valves is now going to be a routine, very easy job.